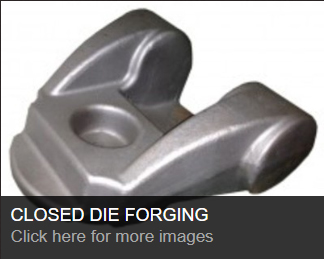

Closed die Forging

This process is also referred to as “impression die forging”.

Steel is heated to a high temperature (below its melting point but high enough to create plasticity in the material) and it is pressed or formed by a press into a die or mold.

Closed die Component Properties

- Good Dimensional accuracy and repeatability in the manufacturing process

- Good use of material, very little waste

- Generally smaller components manufactured with this process

- High production rates

- Limitations

- Can be expensive due to die costs

- Some machining usually necessary