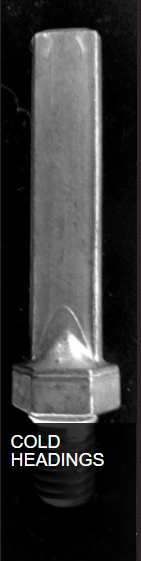

Cold Headings

This process uses only cold workable metals, typically in wire form that is drawn through a mandrel to size and straightened. It is then formed in a series of progressive dies upsetting features on the end portions of the blank. It is then cut off and often threaded in the same operation. This process typically produces a near net shape workpiece, which means the final product is complete. Sometimes requiring additional plating, heat treating, or machining.

- Close tolerances (+/-.002), net shape, minimal scrap

- Excellent surface finish

- Low cost

- Rapid production rate

- Continuous grain flow

- High strength

- Reduced secondaries

- Thread rolling, knurling, and roll forming

- Heat treating, plating, assembly

- Ductile and crack resistant