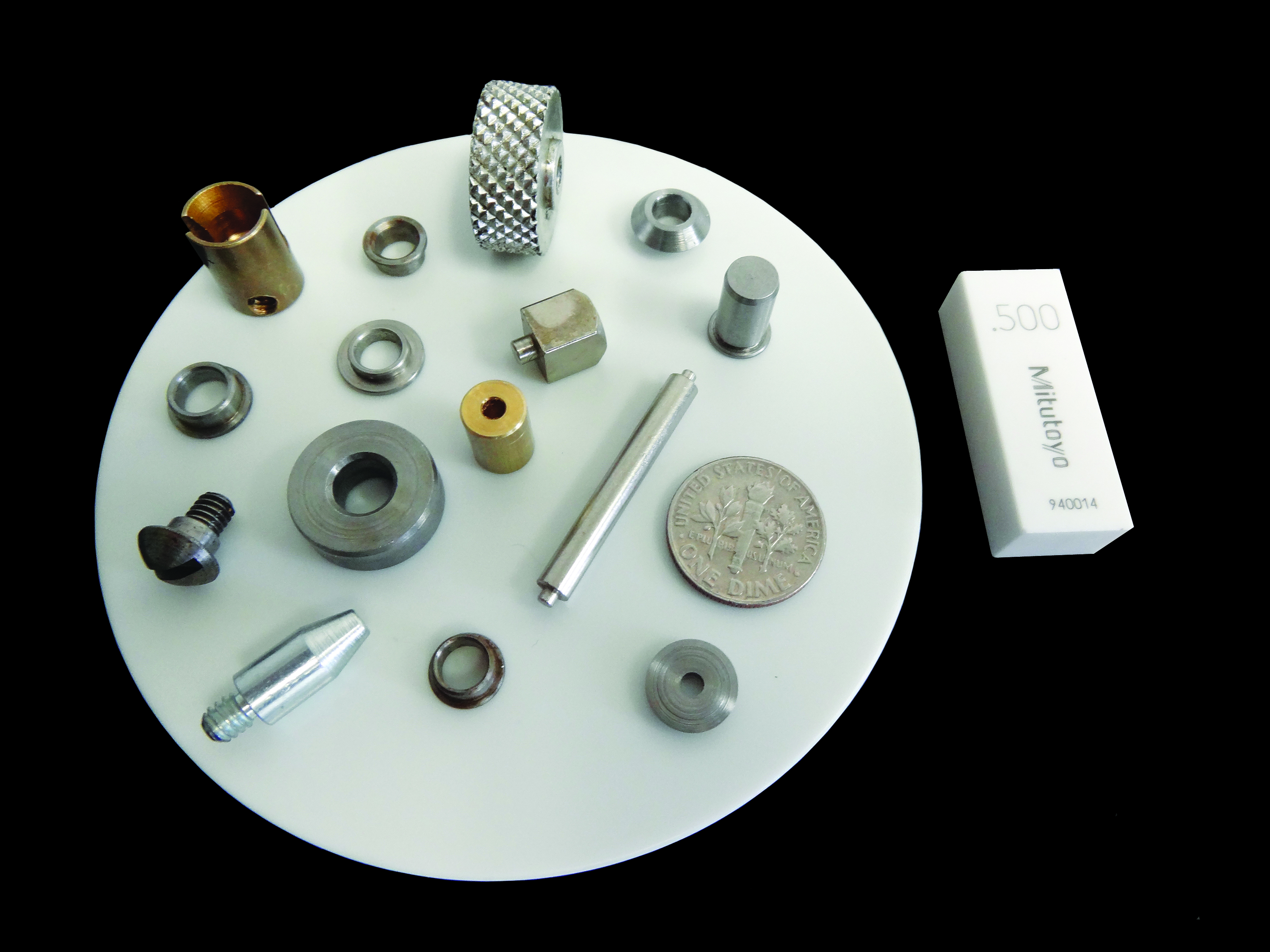

Swiss Machine Parts

Bar stock is fed through spindle into a collet where it rotates and is cut by various tools carried in a turret and on tool slides. Operations include Turning, boring, forming, facing, drilling, tapping, threading, cross drilling, milling.

Machinable ferrous, non-ferrous, and plastic; weldments, castings, forgings, extrusions, bar stock Turning, forming, facing, drilling, tapping, threading, burnishing, boring, cutting off, lettering, swaging, cross drilling, reaming, knurling, milling, broaching, cross milling Swiss turned – 0.010” up to 1.25” diameter with tolerances to .0002”

- Screw machine – 1/8” to 3-1/2” diameter

- Excellent surface finish

- Low cost tooling

- Rapid tool and program changeover-ideal for prototypes and short runs

- High production rate

- Repeatability