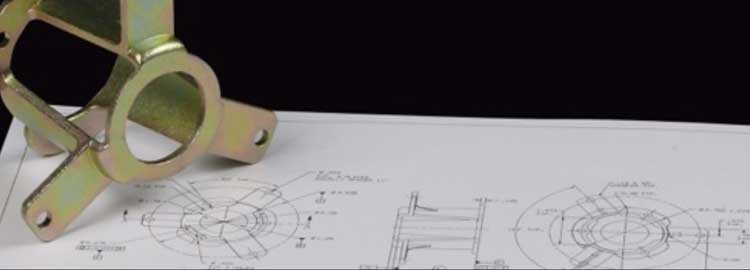

Forged Steering Components

Custom Industrials Companys (CIC) specializes in forged steering components.

Closed Die Forgings

Closed die forging, also known as impression forging, utilizes pressure to compress the forged steering components piece to fill an enclosed die impression. A medium frequency induction heating furnace is used to heat the metal to get the desired forged steering components shapes. As the dies press together, the material is forced to fill the impressions, and the excess metal (flash) is squeezed out. Die forging is the best method to meet tolerances, and results in finished parts that are completely filled and produced with the least amount of flashing.

There are two main types of closed die forging.

Hammer Forgings

Hammer forging is the most common forging for forged steering components individual forgings. In this method, the forged steering components is shaped by an instantaneous application of pressure to a relatively small area. A hammer or ram delivers intermittent blows to the forged section, applying the necessary pressure. Multiple blows with different die shapes are typically used in succession to form forged steering components in order to produce complex shapes. The hammers used are typically dropped from its maximum height, and usually raised by steam or air pressure.

Hammer forging can produce forged steering components in a variety of shapes and sizes, and if sufficiently reduced, it can simultaneously create a high degree of grain refinement. However, hammer forgings typically require tooling or dies to produce anything other than a simple shape such as a round or square forms.

Press Forgings

Somewhat less common is Press Forging is similar to kneading in which a slow and continuous pressure is applied to the forged area. The pressure extends deep into the material, and this process can be done cold or hot. Cold press forging is used on thin, annealed forged steering components, while hot press forging is used on large work such as armor plating, locomotives, and heavy machinery. Press forging offers economic advantages as closer tolerances can be obtained thus less secondary work is needed to produce a finished part to proper tolerances. This method can also be used to create larger forged steering components forgings.

Finish Machining

Finish machining often accompanies many forged steering components, as close dimensional tolerances cannot be obtained with many of the forging processes.

In addition to forged steering components we also provide castings, metal forming, plastics & rubber, and other industrial solutions.

Your forged steering components Solution:

Custom Industrials Company (CIC) is able to handle all your forged steering components needs.

We are focused on delivering quality forged steering components and customized manufacturing parts or products, which comprise of Metal and Plastic components.

Contact us for your no cost forged steering components consultation now.