PETG Plastic Fabrication

Custom Industrials Company (CIC) specializes in PETG plastic fabrication.

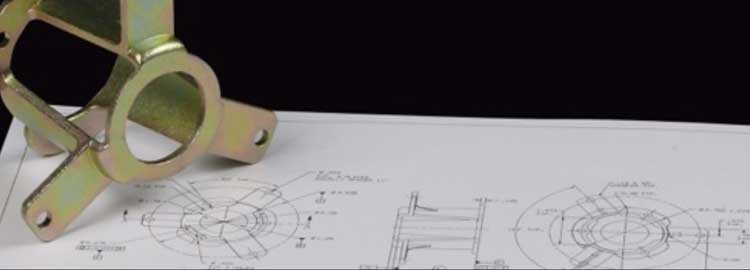

In addition to PETG plastic fabrication we offer are thermoforming, CNC machining, injection molding, forgings, castings, metal forming, rubber fabrication, and industrial consulting services.

What Is Plastic Fabrication?

It's the most common process in the plastic industry for designing, manufacturing, and assembling products from different kinds of plastic demanded by the clients in the market.

The team at Custom Industrials Company knows which materials are best for PETG plastic fabrication.

The possible plastic fabricating materials are UHMW, PTFE, Ploypro, copolymer, PVC, CPVC, PVDF, HDPE, LDPE, acrylic, polycarbonate, acrylic mirror, acrylic twinwall, cutting board plastics, Kydex, ABS, Styrene, PETG, Prismatic Lens, Prismatic Panels, Plastic Louvers Eggcrate, Arm-A-Lite Safety Sleeves, Rigid Plastic, Flexible Tubing, UHMW Tape, Nylon, Delrin, Phenolic, Cast Nylon, Urethane, Polyethylene, polypropylene , Kynar, Halar, General Plastics, Performance Plastics, Lighting Plastics, Engineered Plastics, Corrosion resistant Plastics, and engineered plastic materials.

Generally, 3-axis CNC routing and 5-axis CNC routing machines work for seamless use of these plastic materials. The weight, length, and other aspects of perfecting each part are taken care of with these routing systems. Doing so provides high-speed and high-volume for PETG plastic fabrication and other custom plastic parts manufacturing processes like polypropylene fabrication and acrylic fabrication.

Plastic fabrication has two significant steps for PETG plastic fabrication and all plastic manufacturing.

Plastic Manufacturing

This is the most crucial aspect of PETG plastic fabrication and other custom plastics parts because the type of manufacturing style is specifically chosen for the kind of plastics like PVC, PVDF, acrylic, and others.

Main manufacturing techniques are described later on in this content.

Initially, raw plastic is delivered to the fabrication plant. This material is in the form of raw resins and then converted into an appropriate plastic component for further manufacturing.

These materials are put in two categories: thermoplastics (the materials which are malleable and can be heated before and after production), and thermosets (the materials which are not melted when their production is done).

Plastic Assembling

Activities like bending, drilling, cutting, stamping, and more take place under this category. These steps are usually taken after PETG plastic fabrication manufacturing, and initial melting of the raw plastic is done. However, it might not be a necessary step to take.

But with the help of assembling, further finishing of the prototype is carried out. Which enables the fabricators to mend the first few models before finalizing a design.

Finishing of the product can also be done through polishing, coating, and screening.

Plastic Bending or Compounding

Under this process, two or more plastic materials which can be different or similar, depending upon the demand, are joined together. This takes place through melding, molding, air pressure, or even further cooling of these plastics to form a new one.

The most common benefit of this process is that durable plastic material and products are formed.

Plastic Welding

Another widespread use of plastic fabrication is done through welding, which is also used for metals. This plastic welding is done for thermoplastics like ABS and PVC, as they do not stick together with the help of adhesives.

Plastic Vacuum Forming

Under this kind of plastic formation, a chosen plastic heated to set inside the predefined or manufactured mold. The vacuum pressure helps plastic stick inside the mold. After some time, it is left to cool down.

This method of plastic fabrication is used for medical plastics and instruments like medical trays, bulk chemical storage cases, etc.

However, some plastics need lamination before going under a vacuum form technique. Therefore, experts at Custom Industrials Company check whether the plastic is optimum or not for this process.

Plastic Lamination

The plastic materials like Nylon require lamination before further melding, molding, or heat/air pressure. This lamination process results in plastic prototypes which are durable and pleasing both.

Plastic Foaming

Materials like polyurethane are used for creating froth or foam via plastic foaming process. In return, this foam helps in molding the desired plastic into different shapes and sizes. This process also helps in finishing of products created.

In brief, this method is excellent for providing appeal to the product that is required or is meant to be manufactured.

Plastic Extrusion

For complex medical plastics and industrial plastic manufacturing requirements, extrusion method is widely used. It refers to melting and then cutting the plastic. Furthermore, it is dyed for better presentation as well. But this only happens when the actual size of the design that is fabricated is finalized.

It also helps in creating complex and large shapes associated with the sturdiness and durability that's not easier to find with other fabrication processes in general.

Plastic Fabrication Benefits

Each type of plastic material like General Plastics, Kynar, Engineered Plastics, and others have a distinctive advantage. These can be related to molding, processing prototypes, final designs for medical, and general industry requirements. We will share our PETG plastic fabrication expertise which ensures you have the right plastic material for the job.

Here are some common benefits of Plastic Fabrication found in almost every type of plastic that is used:

Plastic Melting

Plastic gets tamed, melted, and molded pretty easily and conveniently. Other materials like metals, germanium, polymers, silicone, and super-conductors take the time or do not hold the core capabilities that are required to manufacture industrial products the way plastics do.

Plastic Designing & Appearances

Many plastic materials can be painted or designed as per the requirements before final manufacturing processes go down the floor. The same is highly unlikely for hard materials like metals.

Fast Plastic Deliverables

In comparison to other industrial raw materials, plastics have a shorter cycle. For bulk production or processing, plastics are really helpful as they get the job done faster.

Your PETG plastic fabrication Solutions

Custom Industrials Company provides plastic fabrication, taking into consideration space-age processes and technologies at reasonable costs.

Custom Industrials Company (CIC) is able to handle all your PETG plastic fabrication needs.

We are focused on delivering quality PETG plastic fabrication and customized manufacturing parts or products, which comprise of plastic (or metal) components.

Contact us for your no cost PETG plastic fabrication consultation now.

Here is a link to sample plastic parts/images. We would like to handle your PETG plastic fabrication needs!